SimuLearn

SimuLearn: Fast and Accurate Simulator to Support Morphing Materials Design and Workflows

Humphrey Yang, Kuanren Qian, Haolin Liu, Yuxuan Yu, Jianzhe Gu, Matthew McGehee, Yongjie Jessica Zhang, Lining Yao

This is a collaborative effort between the Morphing Matter Lab and the Computational Bio-Modeling Lab at CMU

Publication: SimuLearn: Fast and Accurate Simulator to Support Morphing Materials Design and Workflows (ACM UIST 2020) PDF

Role: Computational toolmaking, ML algorithm design and implementation, application design, dataset generation, documentation

Morphing materials allow us to create new modalities of interaction and fabrication by leveraging the materials’ dynamic behaviors. Yet, despite the ongoing rapid growth of computational tools within this realm, current developments are bottlenecked by the lack of an effective simulation method. As a result, existing design tools must trade-off between speed and accuracy to support a real-time interactive design scenario. In response, we introduce SimuLearn, a data-driven method that combines finite element analysis and machine learning to create real-time (0.61 seconds) and truthful (97% accuracy) morphing material simulators. We use mesh-like 4D printed structures to contextualize this method and prototype design tools to exemplify the design workflows and spaces enabled by a fast and accurate simulation method. Situating this work among existing literature, we believe SimuLearn is a timely addition to the HCI CAD toolbox that can enable the proliferation of morphing materials.

Background

Morphing materials has always been difficult to design due to their dynamic responses. As such, we often use simulations to assist and enable iterative design workflows. Yet, conventional simulation methods each has their own limitations when integrated into a design tool, therefore creating a need for novel simulation methods that offer both extreme speed and high accuracy.

Concept

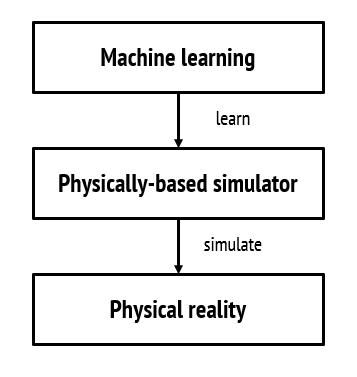

SimuLearn takes inspiration from the human mind’s ability to learn to predict physics by observations. Yet, we use machine learning as a predictor that learns from physically-accurate simulated data to specialize in a mechanical structure. The trained simulator would offer both fast and accurate results that are otherwise difficult - if not impossible - to achieve with other simulation methods.

Contextualized in a Material System

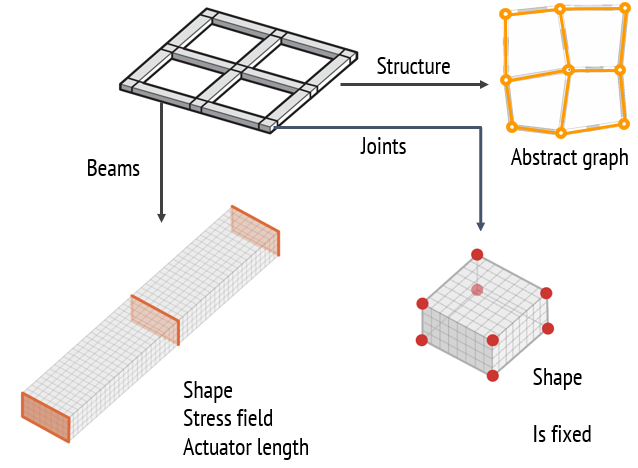

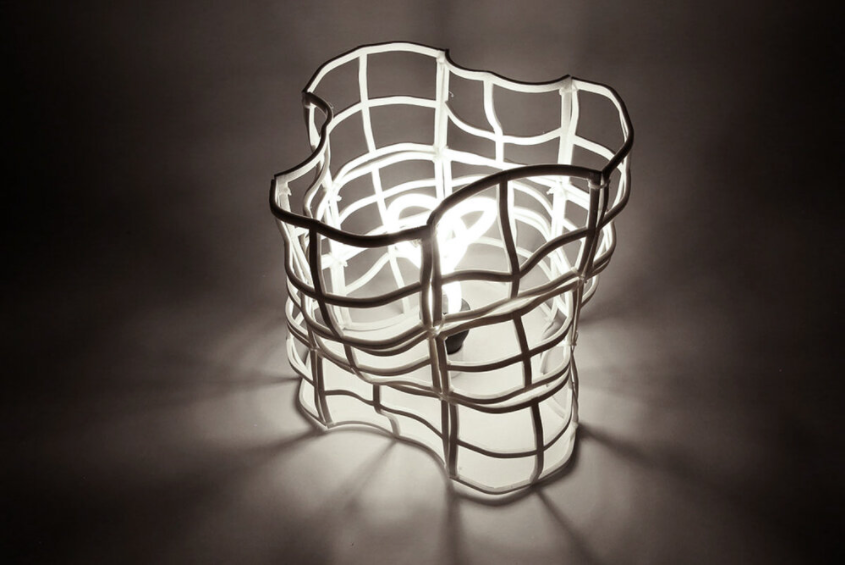

We use 2x2 morphing thermoplastic (PLA) grids to contextualize the SimuLearn concept. The grids are composed of passive joints and bendable beams that transform under heat. Depending on the geometry and actuator layout, the grids may deform into distinctively different shapes. Their physics involves complex material behaviors that are only accountable in numerical methods such as finite element analysis.

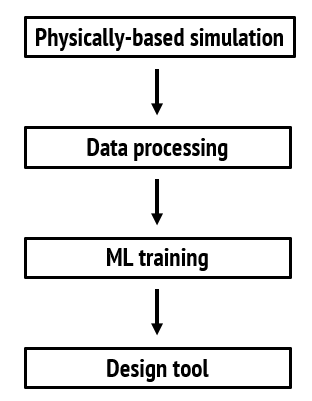

Method

We use a physically-based but slow simulator to produce a dataset. A parametric script was used to auto-generate 2x2 grids that have varying design parameters to cover the design space. In total, we created over 2000 data points for training our model. The datapoints are also geometrically manipulated to create more synthetic data to augment our dataset.

ML-Simulator

A 2x2 grid is represented as an abstract graph, and the nodes and edges are the joints and beams, respectively. The elements are described by their shape, material property, and design, and their connectivity is encoded in the graph structure. This representation is compatible with graph convolutional networks (GCN), which offers better generalizability and accuracy for these graph-like structures. In the end, the simulator had an on-par accuracy with state-of-the-art simulators but runs 1000x faster. The simulation was also parallelizable that affords unique design advantages and features.

SimuLearn for Creative Workflows

SimuLearn’s speed and accuracy enable various design modes, such as:

(forward) supporting users to rapidly design, simulate, and iterate in a digital environment.

(inverse) automating design optimization processes like shape-fitting

(hybrid) allowing computers to co-create with human users with real-time interactivity, such as material-driven parametric design, or quantitative-qualitative (i.e., geometrical and aesthetical) optimization.

Designed Artifacts

SimuLearn augments morphing materials design to become more accurate and interactive, which in turn supports users to navigate increasingly complex design spaces.

A tool like this also helps to democratize these material-driven design practices. In addition to design and engineering, we also acknowledge SimuLearn’s potential as a game or V/AR physics engine.

Source Code and Tool

The project repo including the design tool, the ML source codes, and dataset can be found at: https://github.com/morphing-matter-lab/SimuLearn

Acknowledgment

This research was supported by the Carnegie Mellon University Manufacturing Future Initiative, made possible by the Richard King Mellon Foundation. We thank Angran Li, Daniel Cardoso Llach, Guanyun Wang, Ardavan Bidgoli, and Michael Rivera for providing feedback during the conceptualization stage. We would also like to acknowledge Jesse Gonzalez, Alex Cabrera, and the reviewers’ comments that helped to improve the quality of this paper.